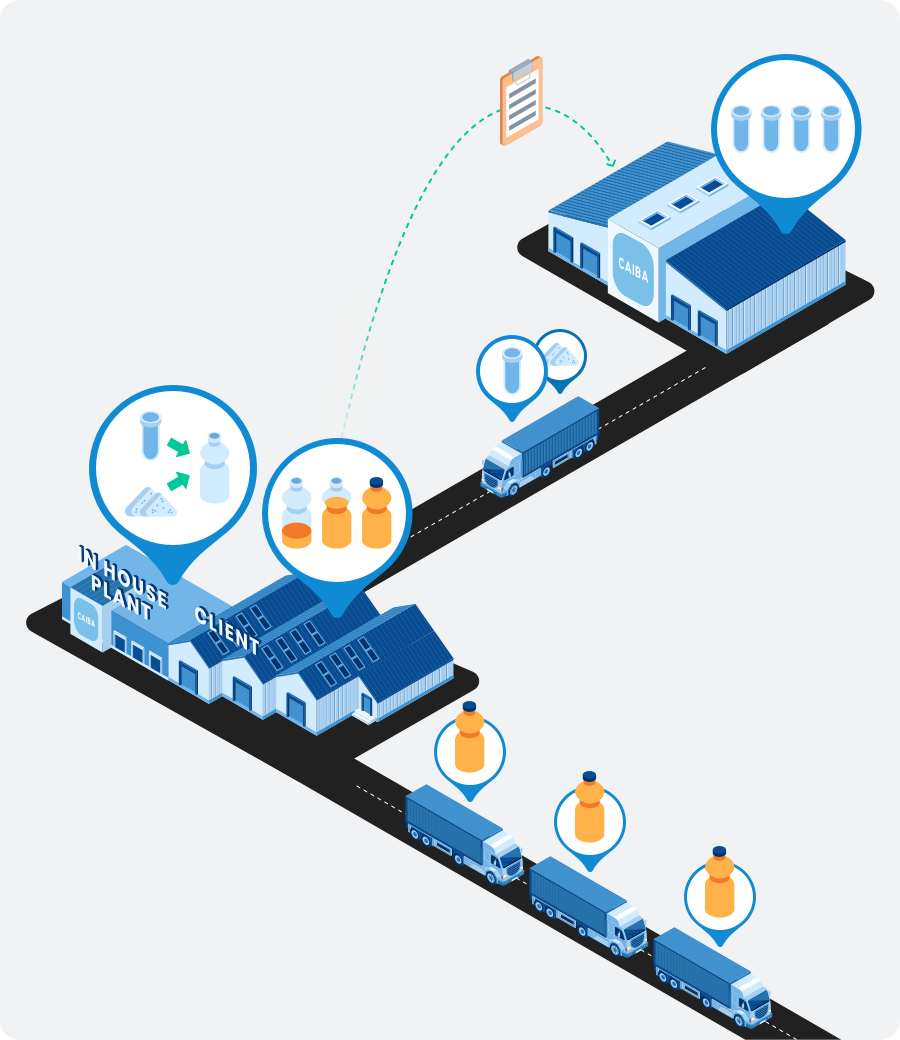

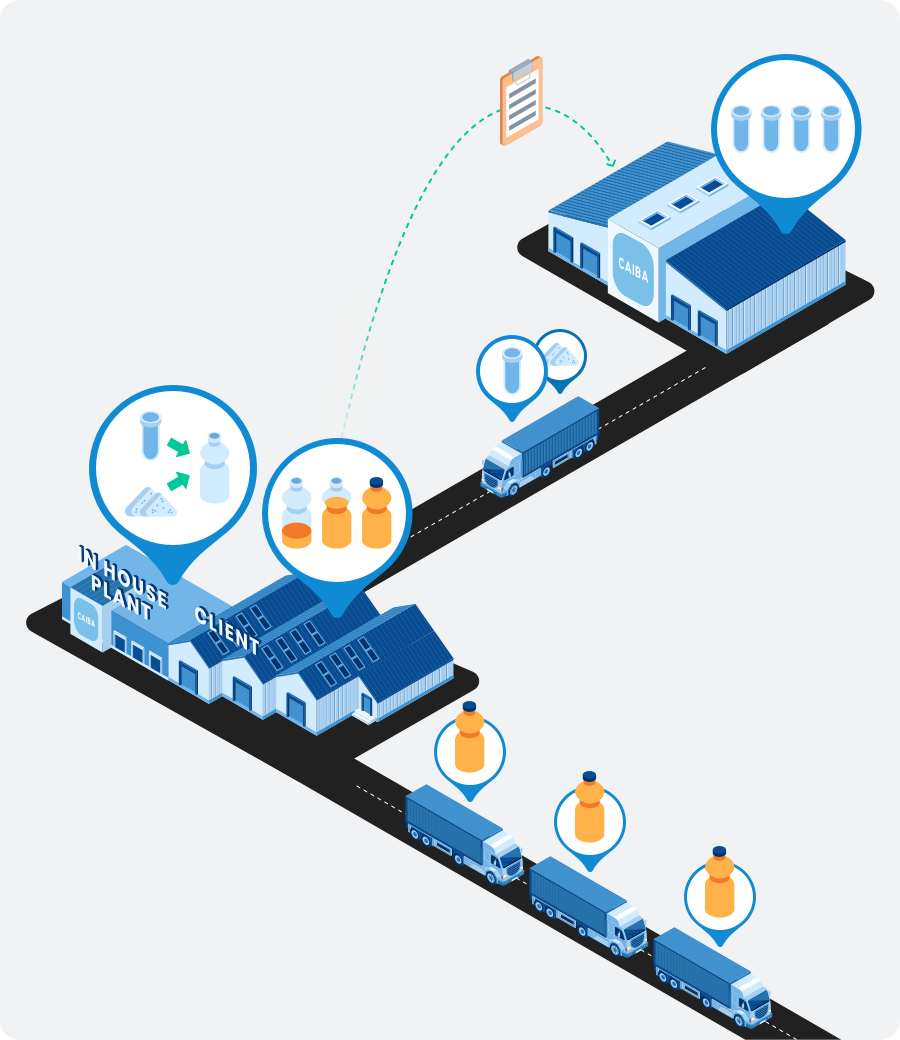

In-house plants

We set up next to our clients in order to save resources and drastically reduce the carbon footprint

A winning proposal

Do you want to drastically reduce your company’s carbon footprint?

How does an in-house plant work?

1

2

3

4

5

6

1

We plan

Our client sends us their packaging schedule.

2

We manufacture the preforms

At the main Caiba plants, we prepare the preforms that are used to manufacture the packaging

The preforms are a much more compact intermediate product than the final packaging.

The preforms are a much more compact intermediate product than the final packaging.

3

We send the preforms

We send the preforms to the in-house plant, located next to the client's packaging line.

This saves heavily on costs and resources.

This saves heavily on costs and resources.

*In the case of polyethylene packaging, we send raw materials to the client’s facility.

4

We finalise the packaging

At the in-house plants, we finalise production of the packaging, putting the preforms through the blowing phase so as to give the packaging its final shape.

In some cases, we undertake the entire process (preform and blowing) such as manufacturing containers in integrated machinery.

In some cases, we undertake the entire process (preform and blowing) such as manufacturing containers in integrated machinery.

5

Product packaging

The packaging moves to the filling line at the pace anticipated by the client.

6

Final distribution

Output of the packaged product to the points of sale.

1

We plan

Our client sends us their packaging schedule.

2

We manufacture the preforms

At the main Caiba plants, we prepare the preforms that are used to manufacture the packaging

The preforms are a much more compact intermediate product than the final packaging.

The preforms are a much more compact intermediate product than the final packaging.

3

We send the preforms

We send the preforms to the in-house plant, located next to the client's packaging line.

This saves heavily on costs and resources.

This saves heavily on costs and resources.

*In the case of polyethylene packaging, we send raw materials to the client’s facility.

4

We finalise the packaging

At the in-house plants, we finalise production of the packaging, putting the preforms through the blowing phase so as to give the packaging its final shape.

In some cases, we undertake the entire process (preform and blowing) such as manufacturing containers in integrated machinery.

In some cases, we undertake the entire process (preform and blowing) such as manufacturing containers in integrated machinery.

5

Product packaging

The packaging moves to the filling line at the pace anticipated by the client.

6

Final distribution

Output of the packaged product to the points of sale.

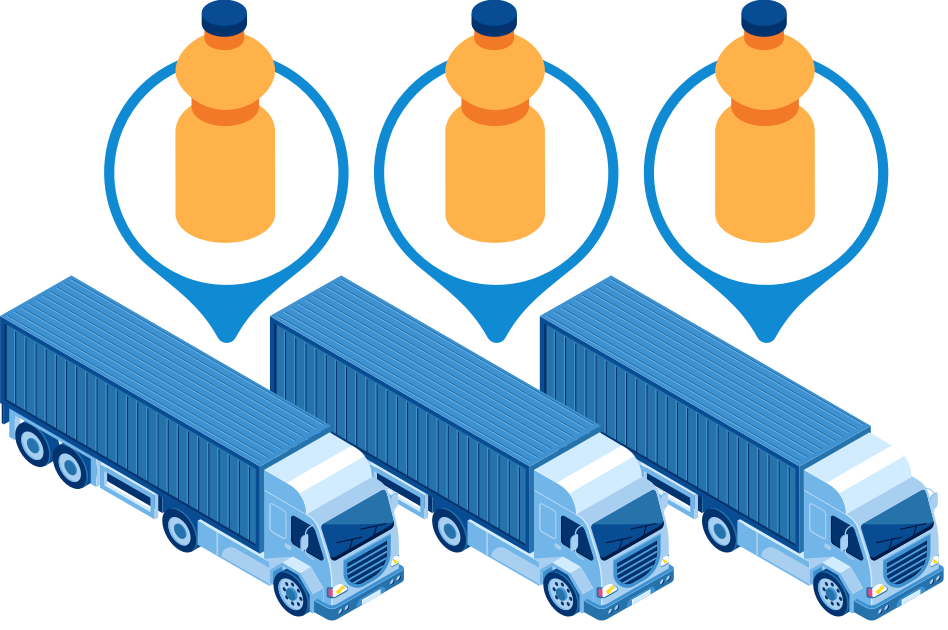

Transport preforms or transport packaging?

A considerable difference

1 truck can transport over 460,000 preforms

To transport the same amount of finished packaging, we would need 8 trucks

An experienced transformed into a priority

12 in-house plants... and growing

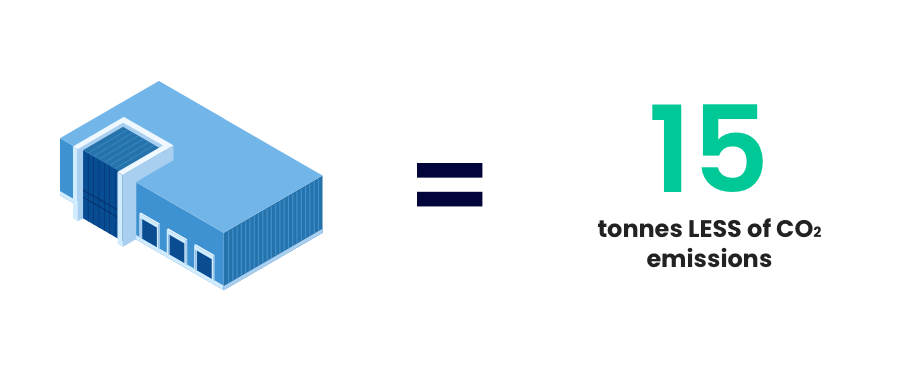

One single in-house plant means that in one year, 15 tonnes of CO2 have not been released into the atmosphere

Want to know more about our products?